Here you will find spare parts and accessories manufactured by our company. We design, test and manufacture car parts ourselves and only then offer them to you.

All parts are designed by CAD and manufactured on CNC machines.

All parts come with a warranty (with conditions).

We respect our customers. We are not trying to impose unnecessary things. You can also purchase each part individually from us.

Attention! This section is updated regularly.

PARTS GROUP 1: BODY / COCKPIT

EXTERIOR

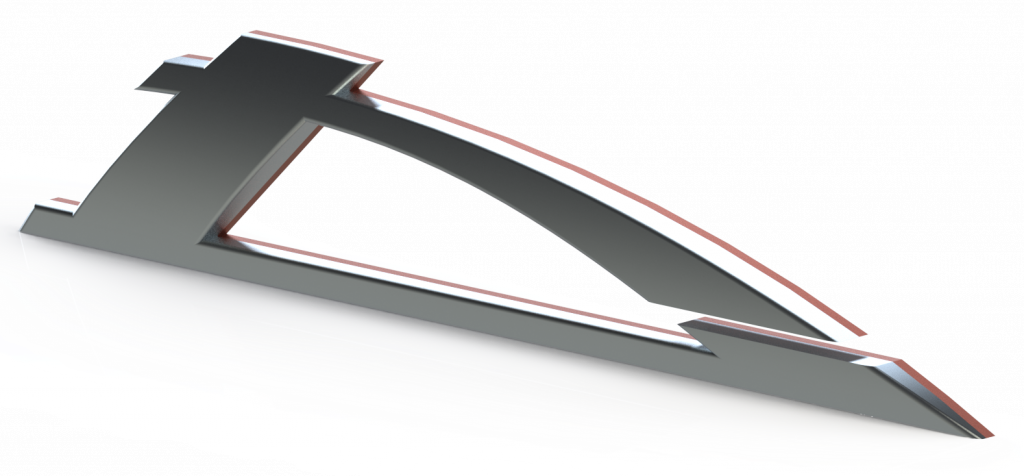

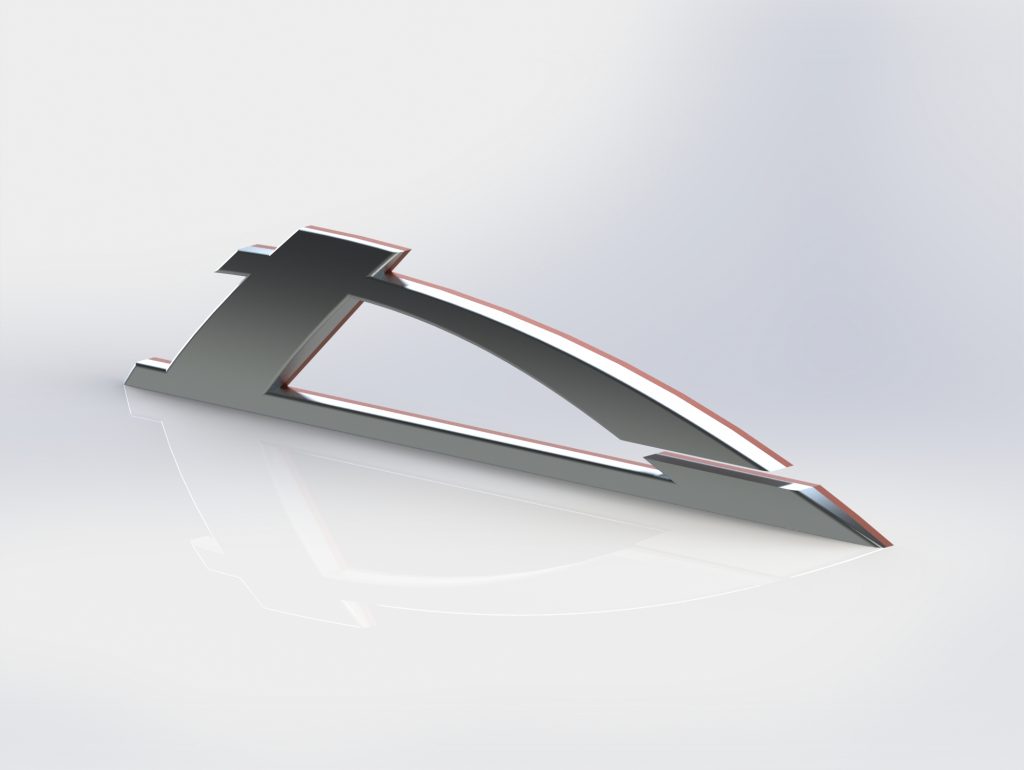

When modernizing a car’s chassis and exterior in particular, our engineers are guided primarily by functional necessity and aerodynamic expediency. Modern technological capabilities and software make it possible to simulate aerodynamic processes with very high accuracy and accurately calculate the optimal passage of air flows.

We actively use this in our projects.

There are absolutely no fake holes or contrived folds in our products.

Real beauty is functional.

INTERIOR

When designing and manufacturing interior elements, the main factors are ergonomics, strength and light weight.

Eg: The driver’s footwell trim has the exact position of the left leg support (width taking into account the number of pedals, angle of inclination). There are also sidewalls for protection from the high temperature emanating from the central tunnel (those who piloted on the track understand).

The product is made of carbon.

Lightweight, practical, functional elements.

COMPONENTS AND MATERIALS

Materials

To produce composite parts, we use materials from various manufacturers. All materials have approvals from the German Federal Aviation Authority (aircraft construction), TÜV Süd (vehicle construction), Germanischer Lloyd (boat construction, wind turbine blades).

Epoxy resin – L, LR 385, LR 285, GL

Hardener – LT, LH 386, LH 285, GL 1, GL 2

Glass fibre – 80 g/m², 105 g/m², 163 g/m², 200 g/m², 220 g/m², 280 g/m², 296 g/m², 390 g/m²

Carbon fibre – 93 g/m², 160 g/m², 200 g/m², 245 g/m²

Aramid fibre – 61 g/m², 110 g/m², 170 g/m²,

Carbon fabric prepreg – C W245-TW2/2/AQ-E323/45 %

Aramid honeycomb – 29 kg/m³

All parts produced by us have material certificates.

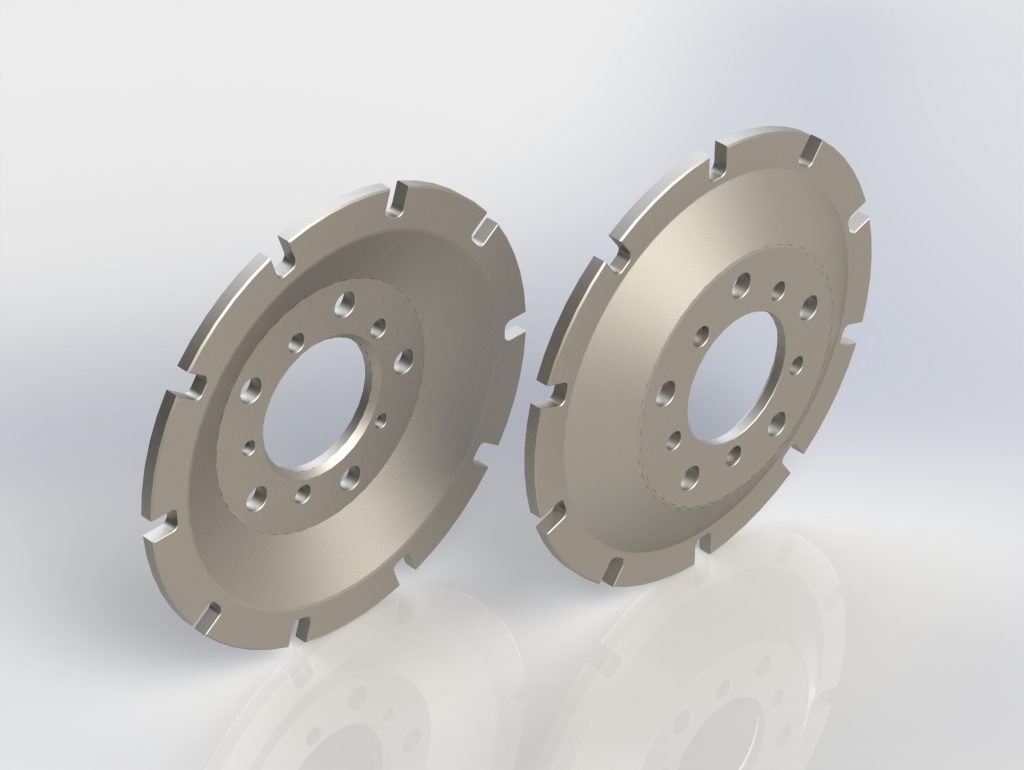

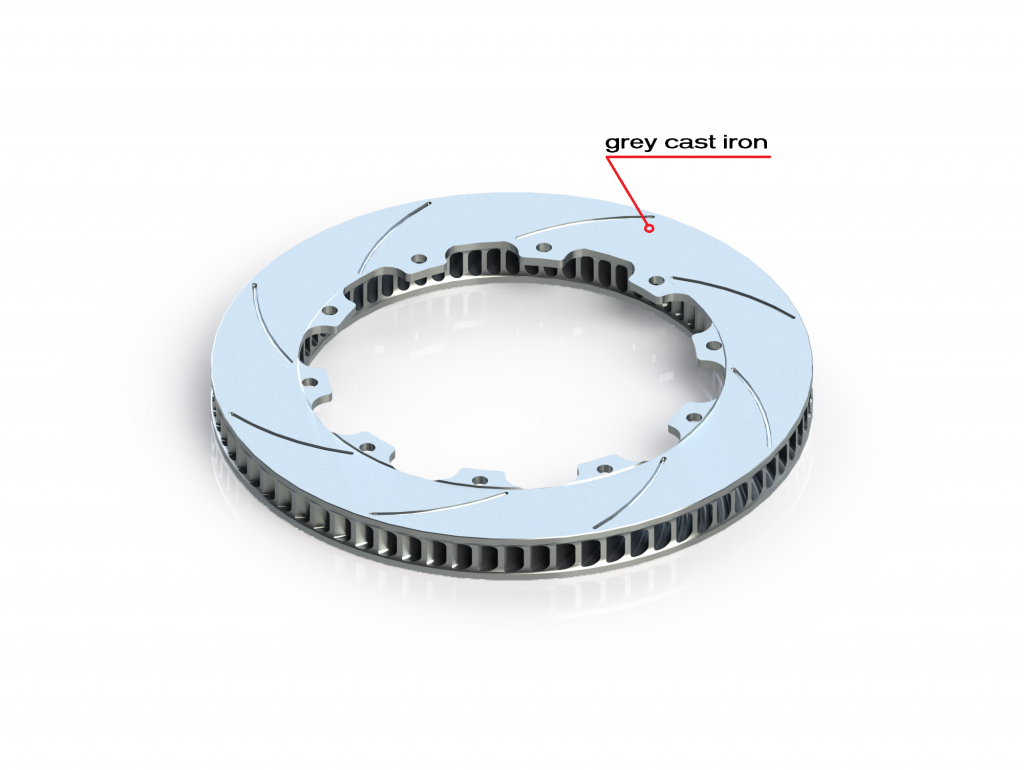

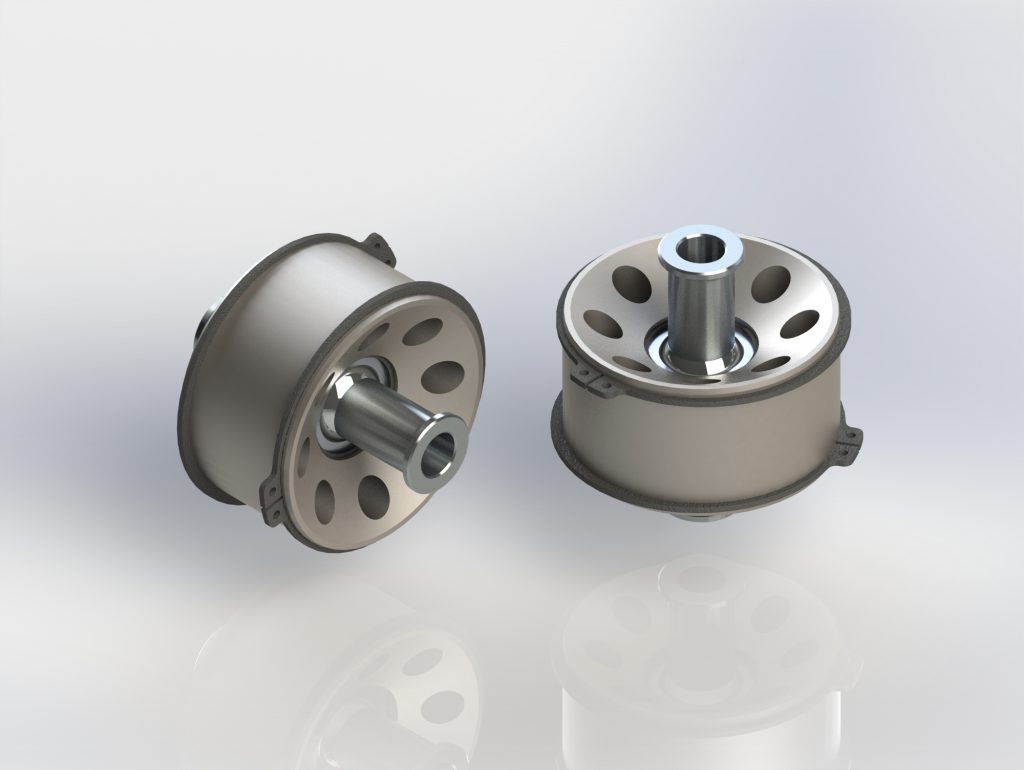

PARTS GROUP 3: WHEELS / BRAKES

BRAKES

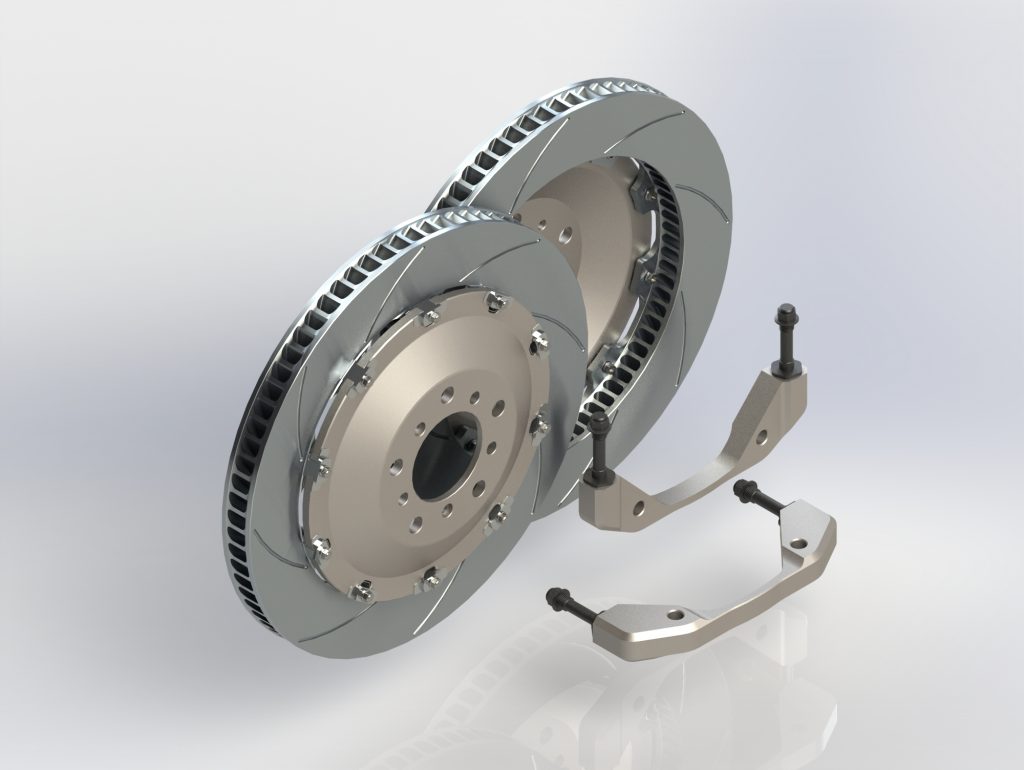

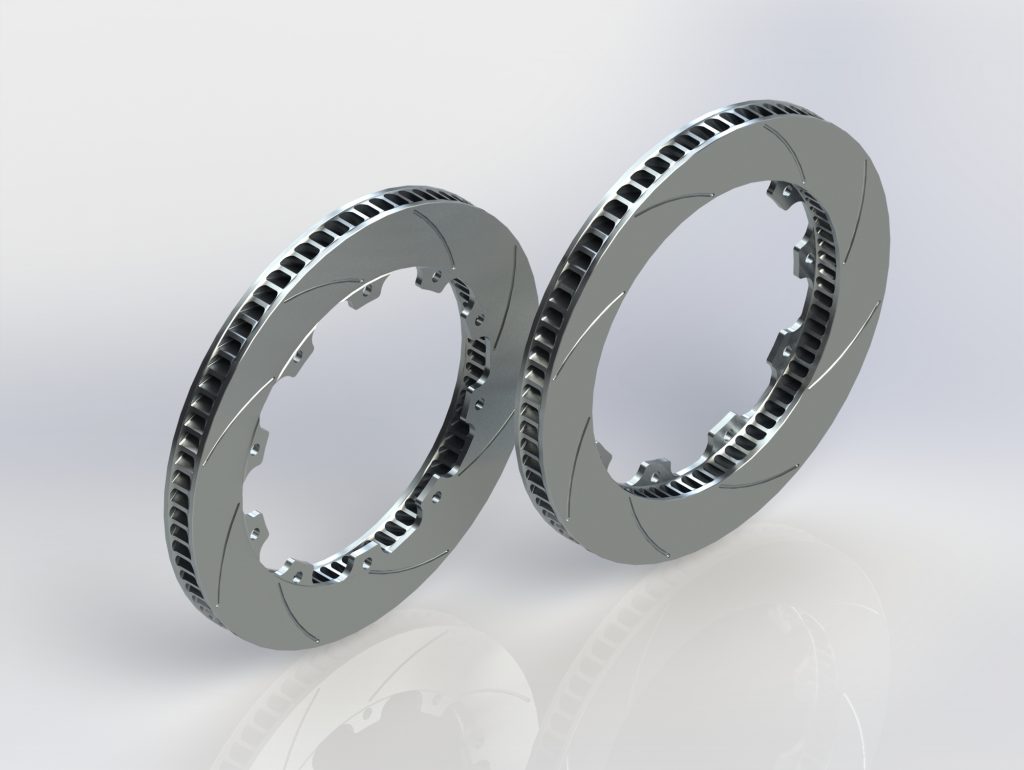

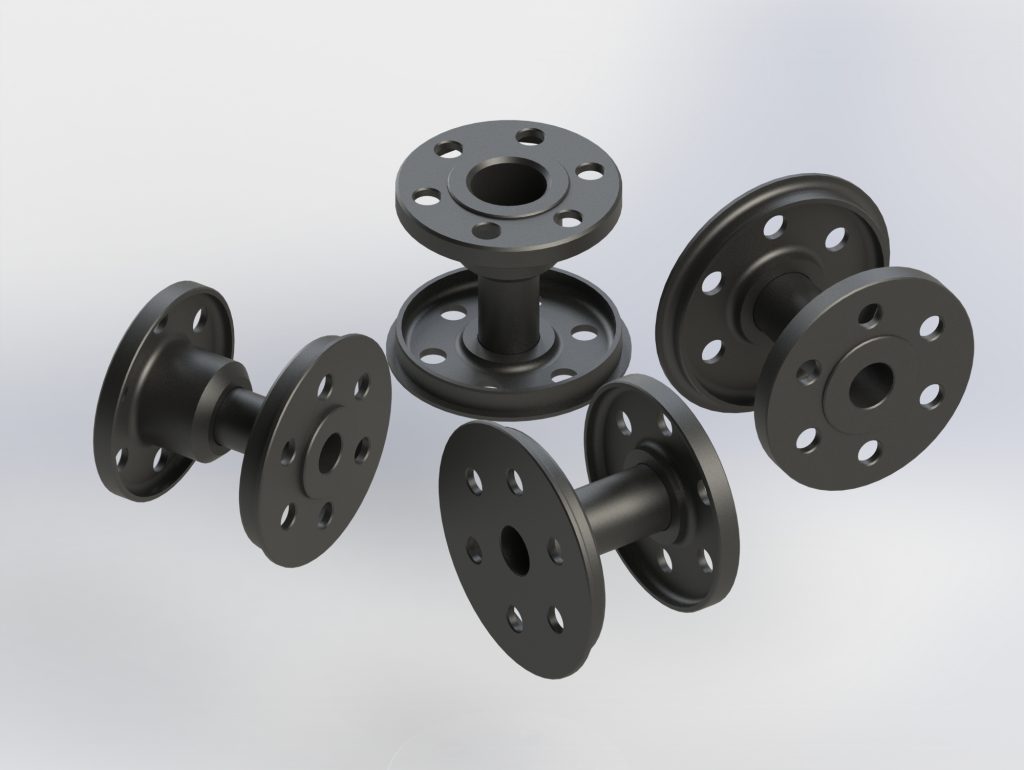

When upgrading the brake system of any car, the most important thing is to maintain balance. To select the correct components, it is necessary to take into account many parameters, such as the weight of the car, weight distribution along the axles, engine power, etc.

– After all, no one needs excessively heavy flywheels to rotate on each wheel – this greatly worsens braking and acceleration dynamics, worsens linear control, increases unsprung masses and the overall weight of the car.

– In addition, no one wants their car to have no baiance of braking forces between the axles.

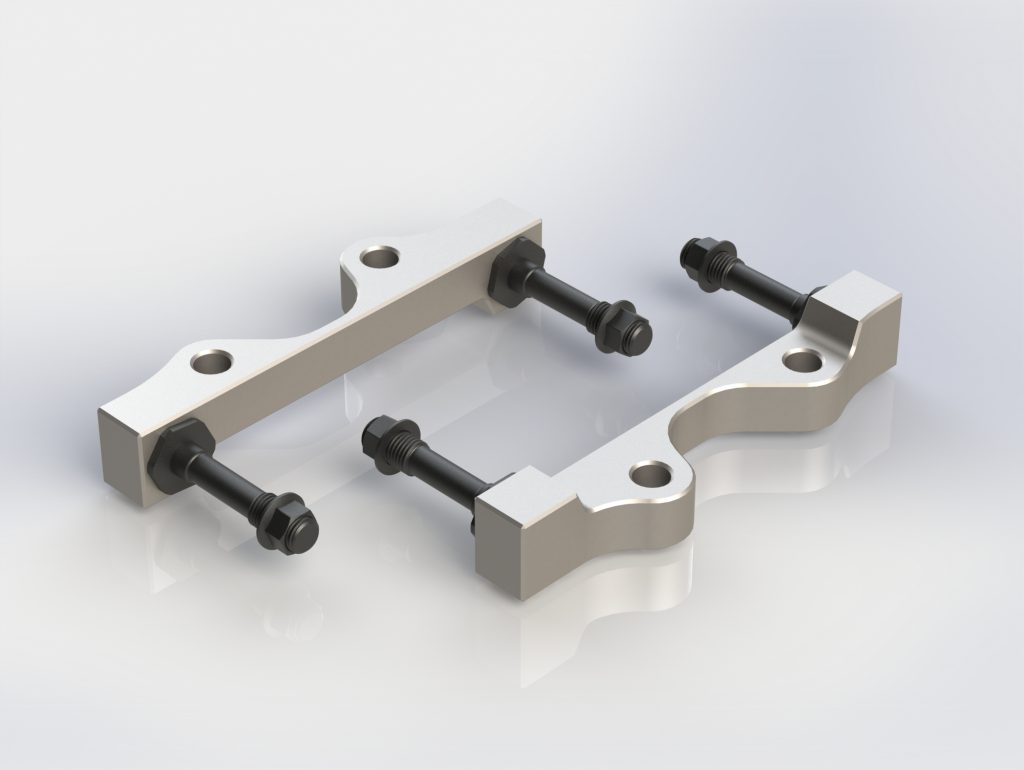

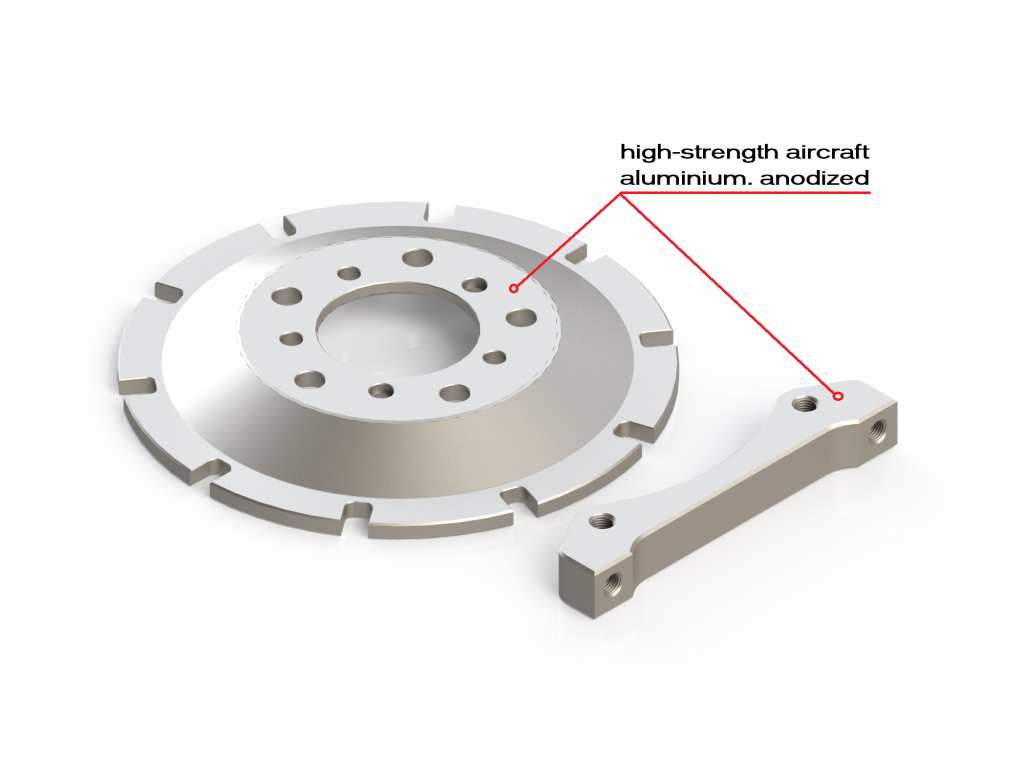

Our engineers have the experience and ability to make a competent individual calculation of the brake system, select the optimal components and manufacture the necessary adapters for brake calipers and bells for brake discs.

We can also always calculate the most efficient cooling system.

From us you can purchase not only a set of parts, but also each part separately.

Front Brakes

Rear Brakes

COMPONENTS AND MATERIALS

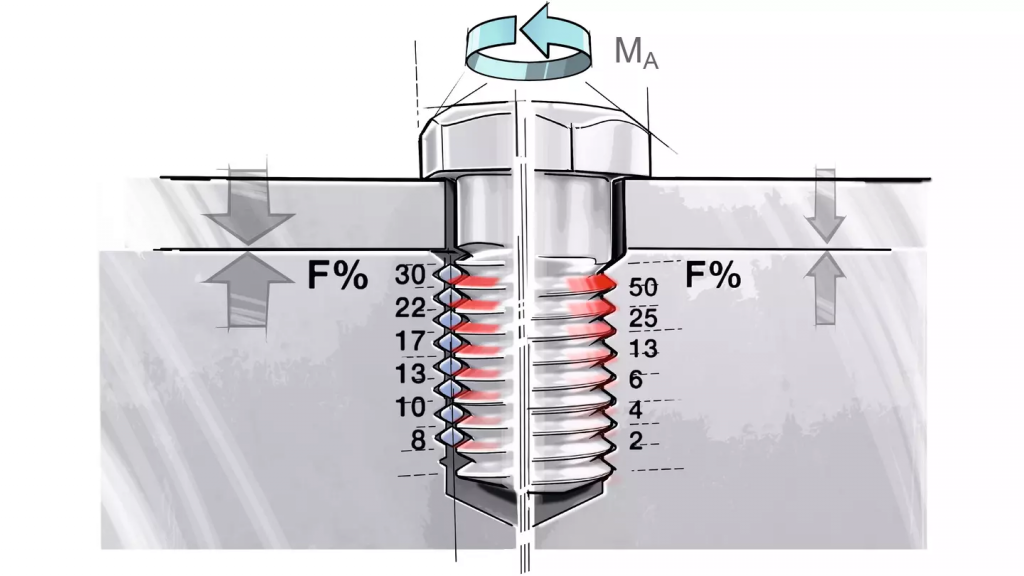

Components

Thread reinforcement wherever low shear strength materials – such as aluminium or aluminium-magnesium alloys – are used. In these applications thread inserts generate heat-resistant, wear-resistant and high-strength thread of the highest precision.

No internal thread wear, even with frequent use.

Materials

In the manufacture of our products we use the following materials:

1.4057 – high-strength steel, rustproof

1.7225 / 1.7227 – tool steel, alloyed tempered

1.0718 – free-cutting steel, browned

1.4305 – stainless steel

EN AW-7075 T6 / EN AW-6082 T6 – high-strength aircraft aluminium

All parts produced by us have material certificates.

PARTS GROUP 4: FRONT AXLE / STEERING

MODULAR Dt-KIT

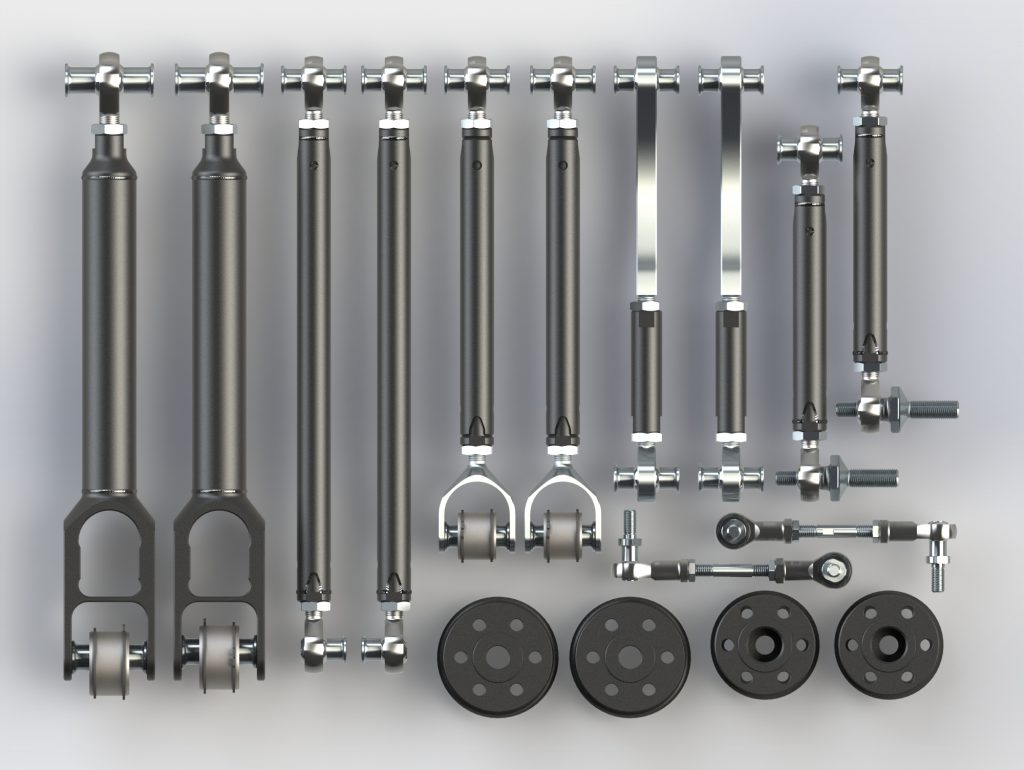

Our engineers have specially developed a variety of modular Dt kits for street cars. This allowed us to fulfill the various necessary specific technical requirements, as well as to satisfy the individual preferences of our customers.

Dt kits differ in the degree of optimization of wheel suspension and are classified into the following categories:

Dt.1 – more sportiness while maintaining practicality.

Dt.2 – a smart choice to achieve decent results.

Dt.3 – the best proven solutions from real motorsport for a street car.

Dt.4 – no compromises, only the highest final result on the track.

From us you can purchase not only a set of parts, but also each part separately.

Dt.1-FR – more sportiness while maintaining practicality.

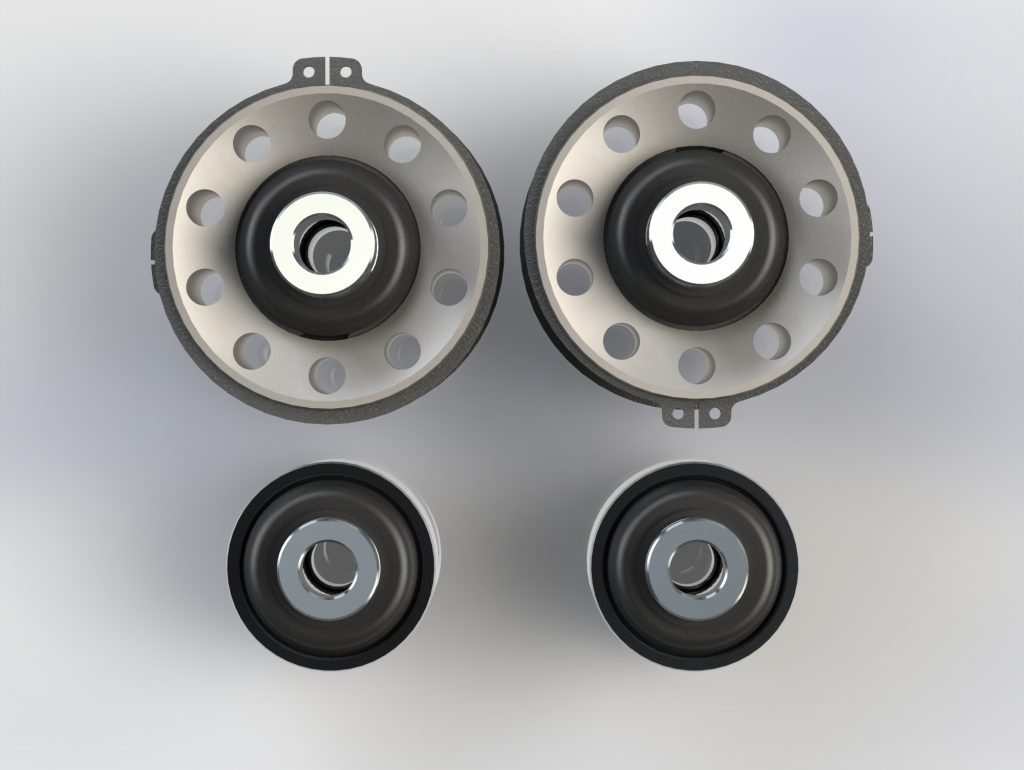

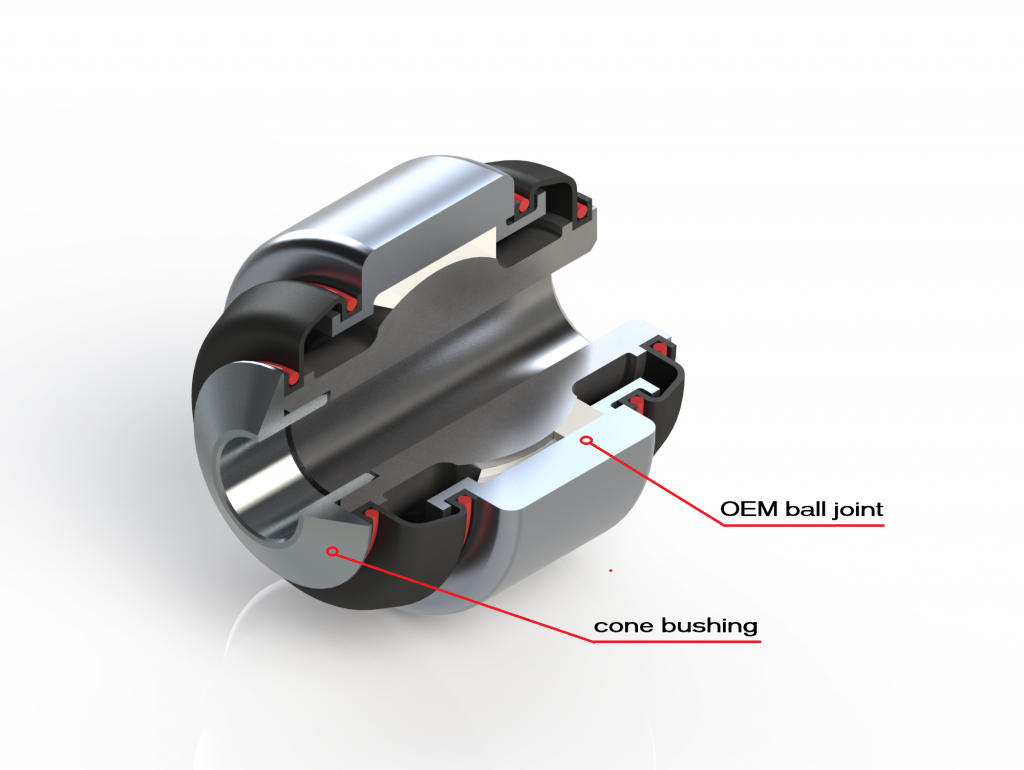

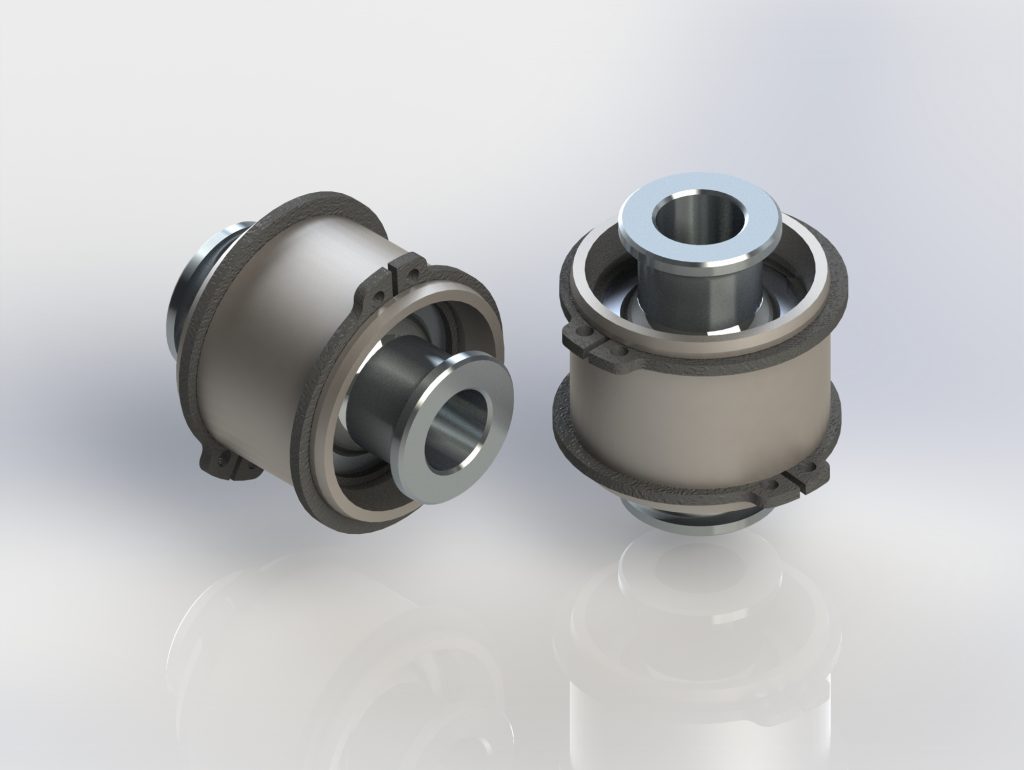

This kit involves replacing all silent blocks with ball joints. Ball joints are OEM quality, modernized for trouble-free installation into standard control arms.

Dt.1 kit is the perfect compromise. It is suitable for both regular all-season driving on public roads and for visiting the race track.

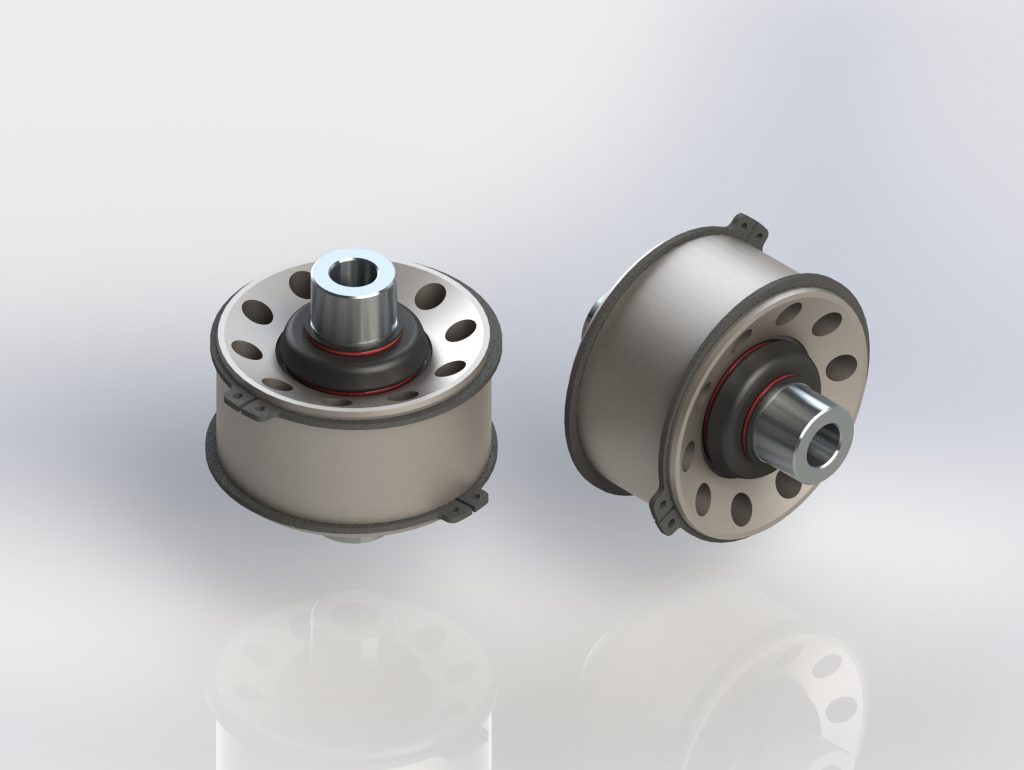

Dt.2-FR – a smart choice to achieve decent results.

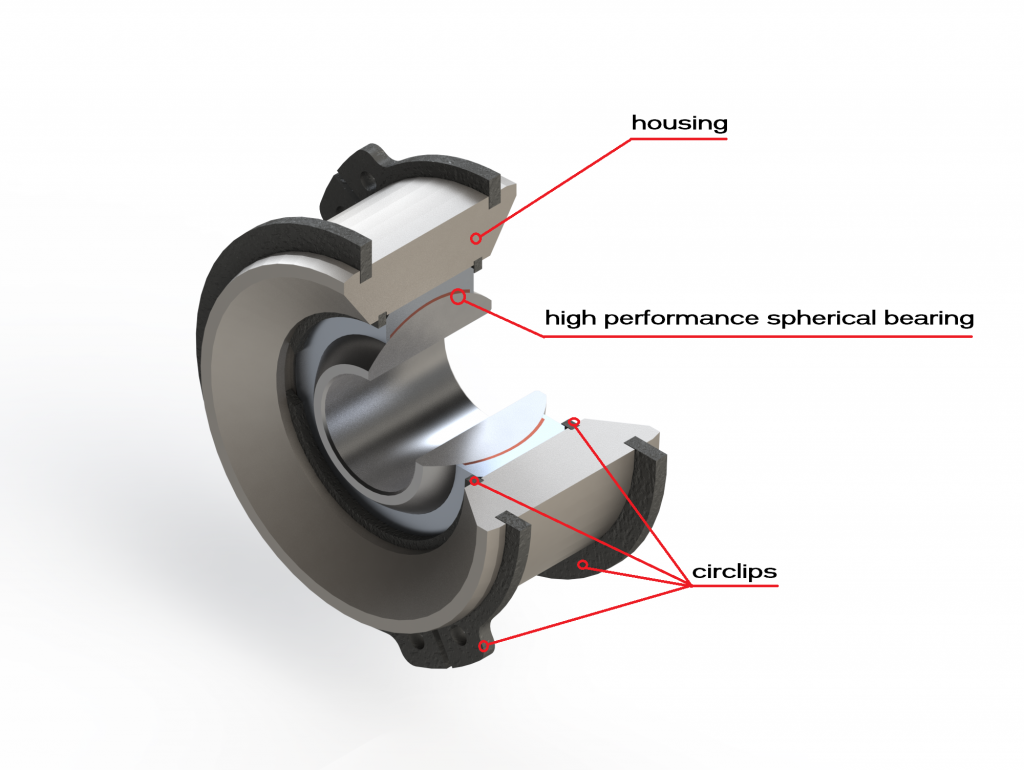

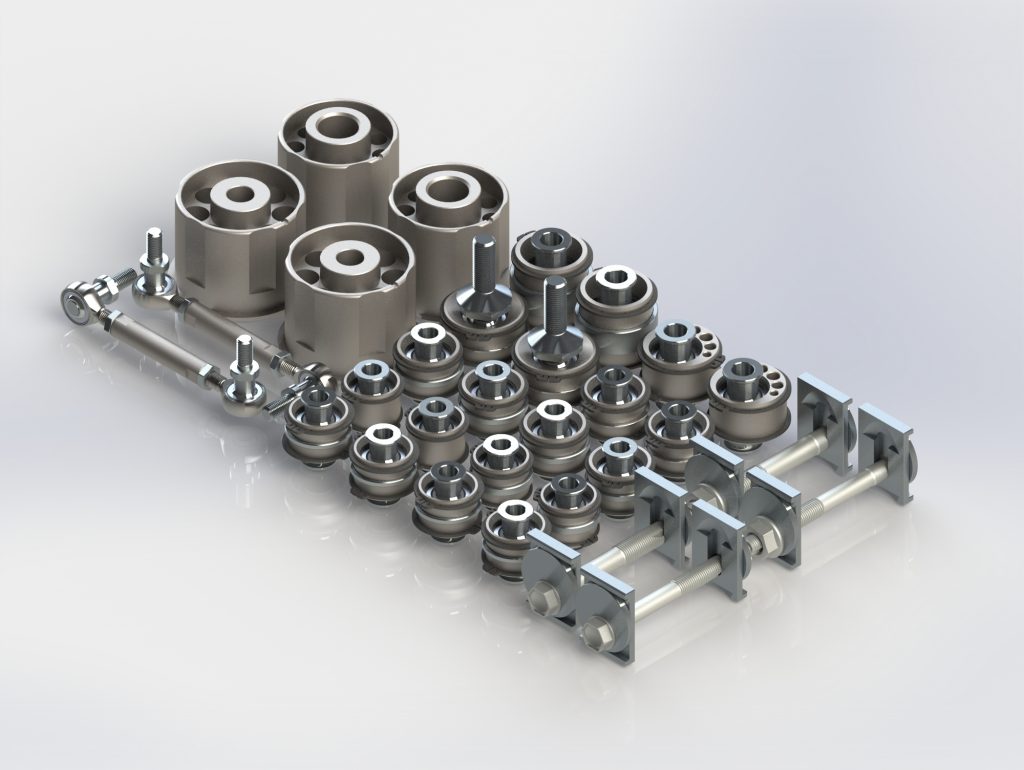

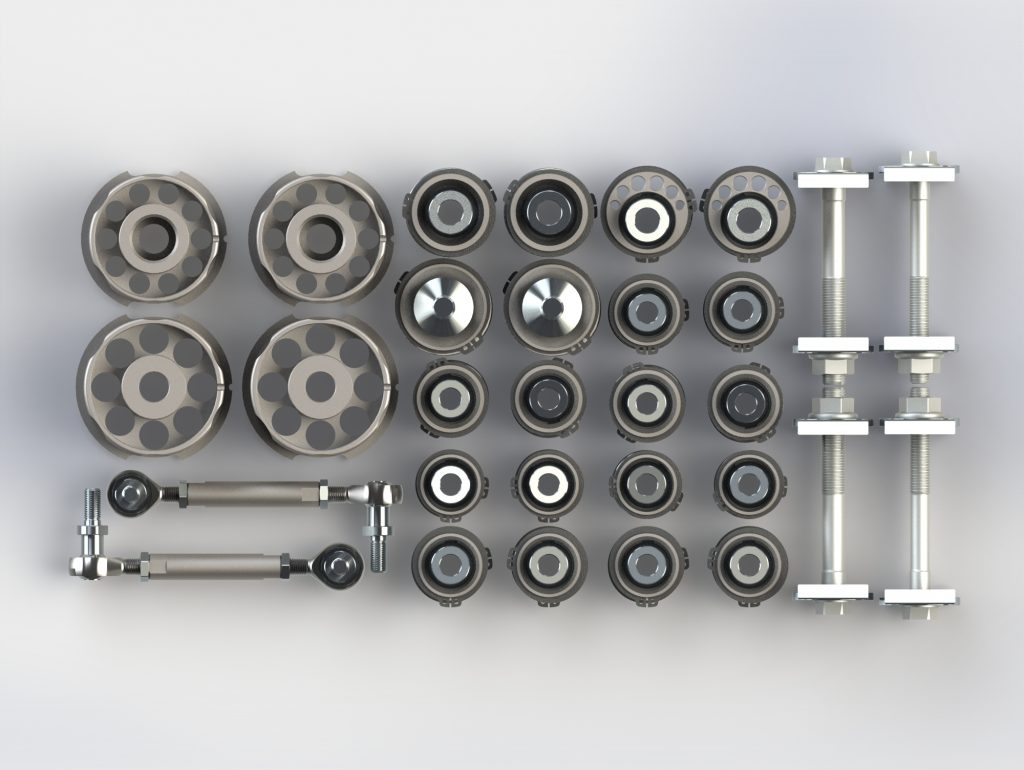

This kit involves the integration of spherical bearings with OEM control arms. All spherical bearings are in motorsport specification with corresponding characteristics.

The Dt.2 kit allows you to significantly increase stability and response without extra costs.

(For reference! TGR engineers used a similar method of upgrading the wheel suspension for the Toyota GR Supra GT4.)

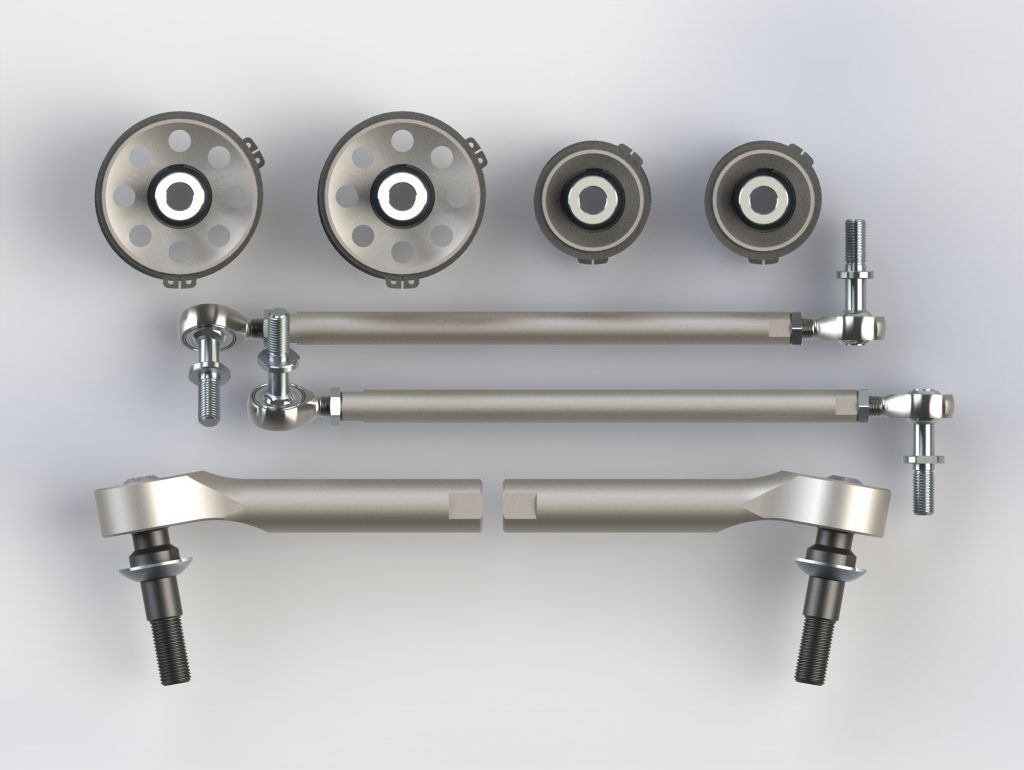

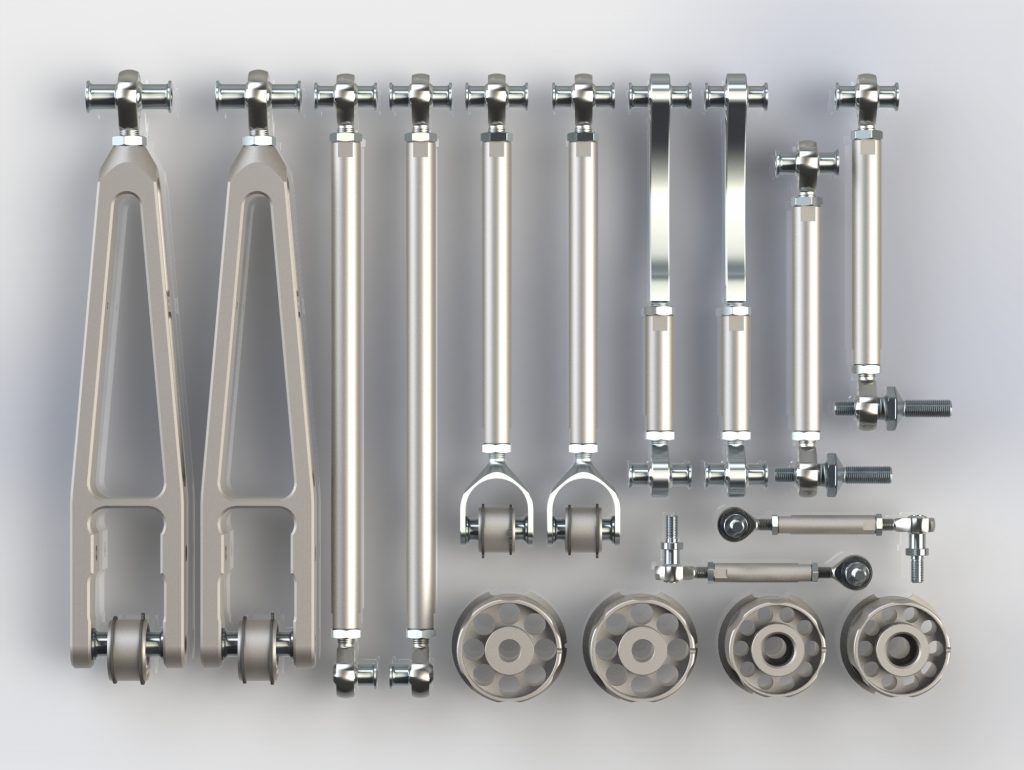

Dt.3-FR – the best proven solutions from real motorsport for a street car.

This kit involves the complete replacement of all OEM control arms with alternative ones optimized for weight and strength.

Dt.3 kit is aluminum rods and high performance rod ends designed to withstand the extreme loads of motorsports.

(For reference! BMW M4 GT4 wheel suspension parts have comparable strength characteristics.)

All arms are supplied with precisely adjusted lengths.

Dt.3.2-FR – the best proven solutions from real motorsport for a street car (an alternative version of Dt.3-FR).

Steel rods are used here instead of aluminum. This option was created after numerous requests from our customers.

We try to satisfy any wishes.

This kit involves the complete replacement of all OEM control arms with alternative ones optimized for weight and strength.

Dt.3.2 kit is steel rods and high performance rod ends designed to withstand the extreme loads of motorsports.

All arms are supplied with precisely adjusted lengths.

COMPONENTS AND MATERIALS

Components

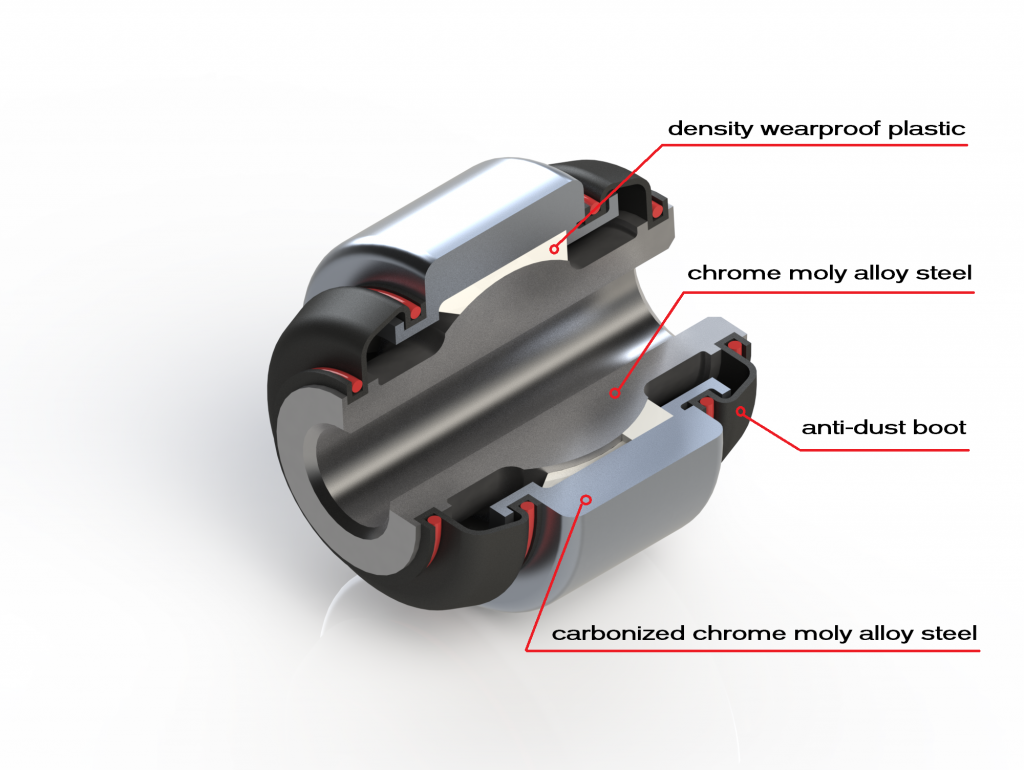

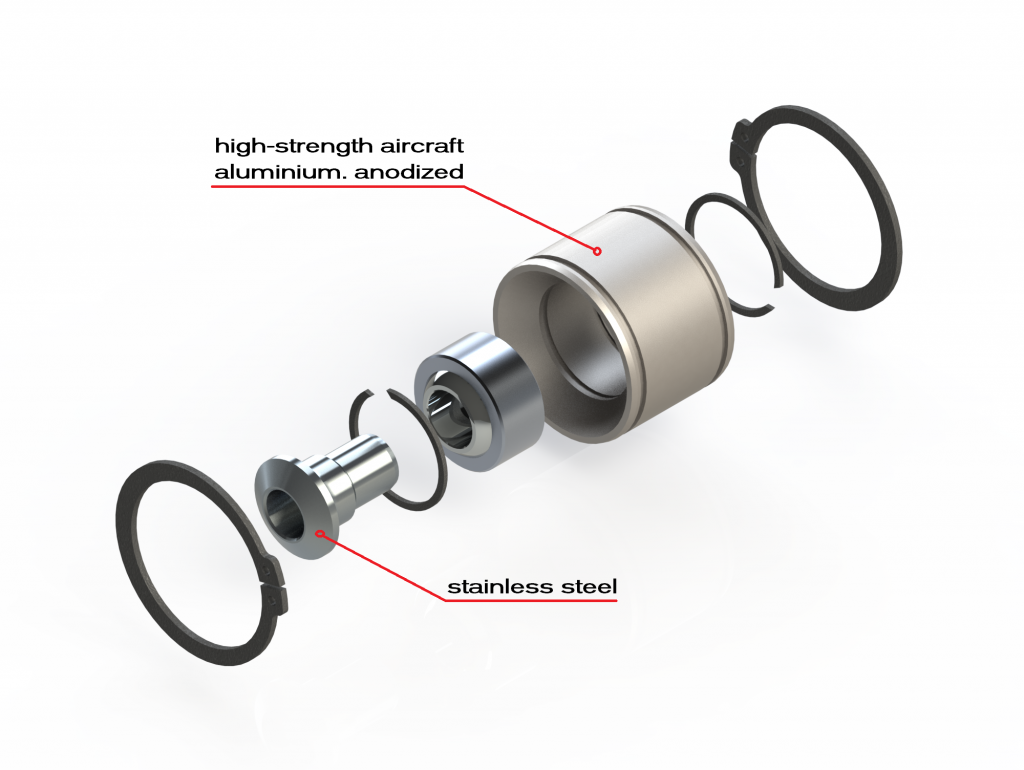

The upgraded ball joints are created by our engineers based on serial parts. This means that the service life and performance characteristics of these spare parts fully comply with the car manufacturer’s standards.

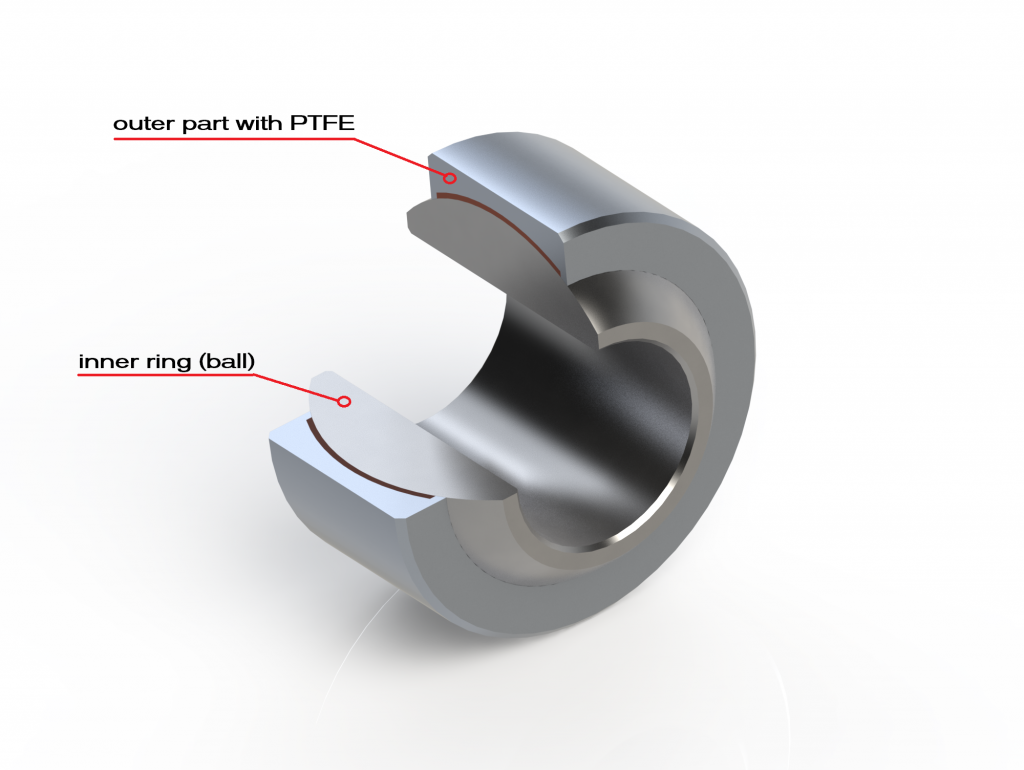

When designing uniball joints, our engineers took into account the factor of production cost, but without compromising quality and reliability. The spherical bearings used in our uniball joints are from leading manufacturers in Germany and Italy. All materials meet the highest requirements of motorsport. Sealed uni-ball joints are available on request.

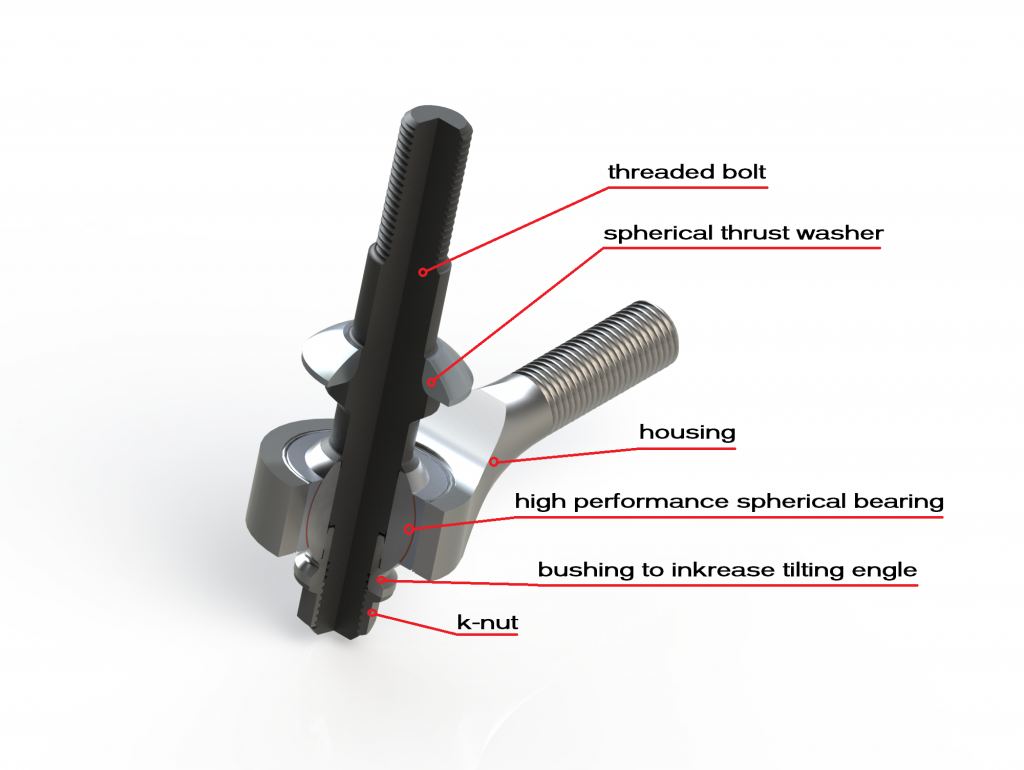

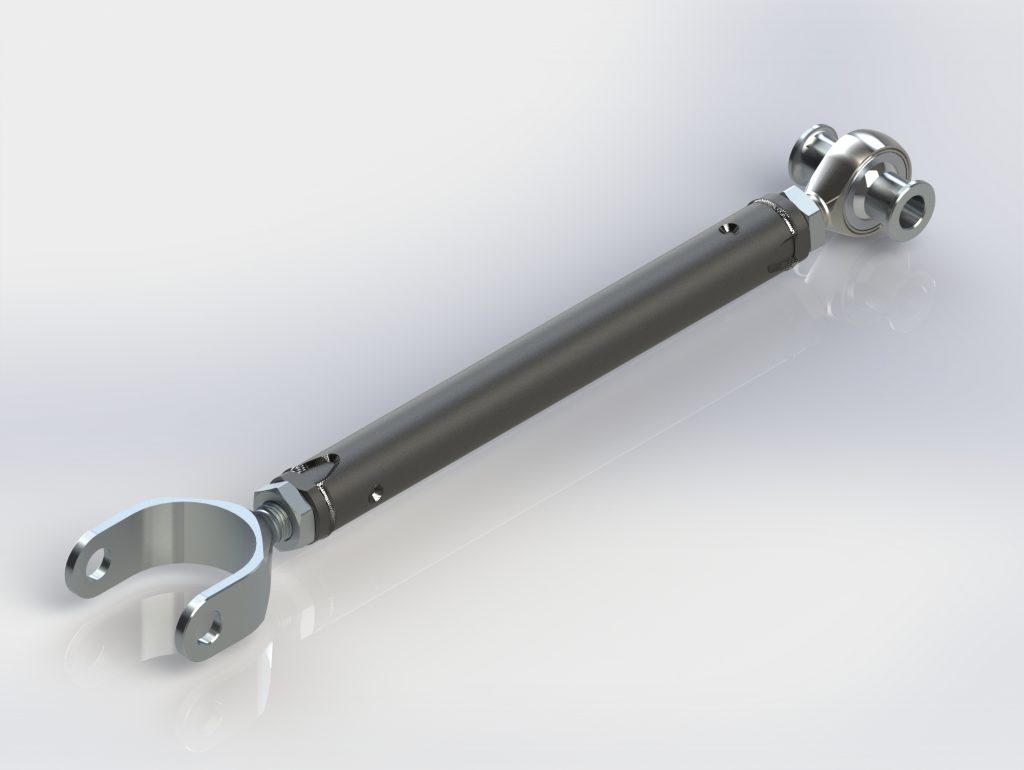

The high performance rod ends are developed by our engineers took into account design requirements and specific operating conditions. The spherical bearings used in our rod ends are from leading manufacturers in Germany and Italy. All materials meet the highest requirements of motorsport.

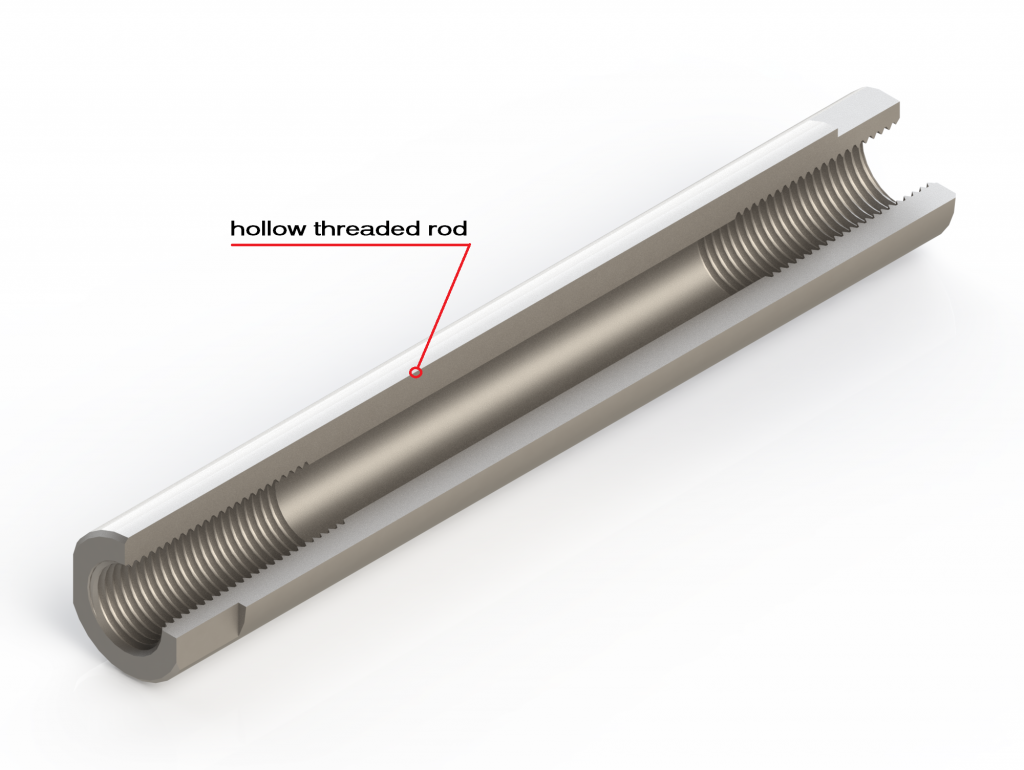

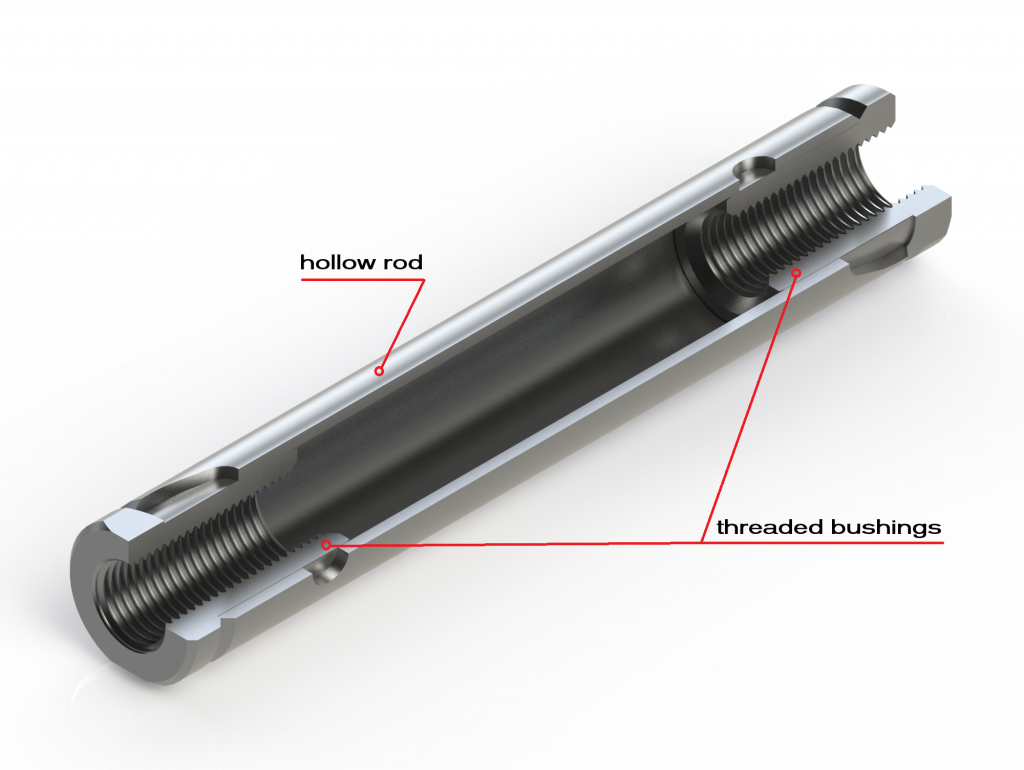

When designing rods, our engineers take into account the relationship between two main parameters – weight and strength. Aluminum rods are made of high-strength aircraft aluminum, steel rods are made of high-strength steel. All rods are hollow with a carefully calculated thickness.

We use spherical bearings for motorsport from leading manufacturers such as: Hirschmann, Fluro, Rodobal.

Database of spherical bearings:

SCHP14 / static Co – 105,0 kN / dynamic C – 67,0 kN

SCHP16 / static Co – 130,0 kN / dynamic C – 84,0 kN

GXSW14.29MS / static Co – 70,0 kN / dynamic C – 50,5 kN

GXSW16.32MS / static Co – 88,0 kN / dynamic C – 63,0 kN

RG14 MT.29 / static Co – 69,8 kN

RG16 MT.32 / static Co – 87,8 kN

Materials

In the manufacture of our products we use the following materials:

1.4057 – high-strength steel, rustproof

1.7225 / 1.7227 – tool steel, alloyed tempered

1.0718 – free-cutting steel, browned

1.4305 – stainless steel

EN AW-7075 T6 / EN AW-6082 T6 – high-strength aircraft aluminium

All parts produced by us have material certificates

PARTS GROUP 5: REAR AXLE / DIFFERENTIAL

MODULAR Dt-KIT

Our engineers have specially developed a variety of modular Dt kits for street cars. This allowed us to fulfill the various necessary specific technical requirements, as well as to satisfy the individual preferences of our customers.

Dt kits differ in the degree of optimization of wheel suspension and are classified into the following categories:

Dt.1 – more sportiness while maintaining practicality.

Dt.2 – a smart choice to achieve decent results.

Dt.3 – the best proven solutions from real motorsport for a street car.

Dt.4 – no compromises, only the highest final result on the track

From us you can purchase not only a set of parts, but also each part separately.

Dt.1-RR – more sportiness while maintaining practicality.

This kit involves replacing all silent blocks with ball joints. Ball joints are OEM quality, modernized for trouble-free installation into standard control arms.

Dt.1 kit is the perfect compromise. It is suitable for both regular all-season driving on public roads and for visiting the race track.

Dt.2-RR – a smart choice to achieve decent results.

This kit involves the integration of spherical bearings with OEM control arms. All spherical bearings are in motorsport specification with corresponding characteristics.

The Dt.2 kit allows you to significantly increase stability and response without extra costs.

(For reference! TGR engineers used a similar method of upgrading the wheel suspension for the Toyota GR Supra GT4.)

Dt.3-RR – the best proven solutions from real motorsport for a street car

This kit involves the complete replacement of all OEM control arms with alternative ones optimized for weight and strength.

Dt.3 kit is aluminum rods and high performance rod ends designed to withstand the extreme loads of motorsports.

(For reference! BMW M4 GT4 wheel suspension parts have comparable strength characteristics.)

All arms are supplied with precisely adjusted lengths.

Dt.3.2-RR – the best proven solutions from real motorsport for a street car (an alternative version of Dt.3-RR).

Steel rods are used here instead of aluminum. This option was created after numerous requests from our customers.

We try to satisfy any wishes.

This kit involves the complete replacement of all OEM control arms with alternative ones optimized for weight and strength.

Dt.3.2 kit is steel rods and high performance rod ends designed to withstand the extreme loads of motorsports.

All arms are supplied with precisely adjusted lengths.

COMPONENTS AND MATERIALS

Components

The upgraded ball joints are created by our engineers based on serial parts. This means that the service life and performance characteristics of these spare parts fully comply with the car manufacturer’s standards.

When designing uniball joints, our engineers took into account the factor of production cost, but without compromising quality and reliability. The spherical bearings used in our uniball joints are from leading manufacturers in Germany and Italy. All materials meet the highest requirements of motorsport. Sealed uni-ball joints are available on request.

The high performance rod ends are developed by our engineers took into account design requirements and specific operating conditions. The spherical bearings used in our rod ends are from leading manufacturers in Germany and Italy. All materials meet the highest requirements of motorsport.

When designing rods, our engineers take into account the relationship between two main parameters – weight and strength. Aluminum rods are made of high-strength aircraft aluminum, steel rods are made of high-strength steel. All rods are hollow with a carefully calculated thickness.

We use spherical bearings for motorsport from leading manufacturers such as: Hirschmann, Fluro, Rodobal.

Database of spherical bearings:

SCHP14 / static Co – 105,0 kN / dynamic C – 67,0 kN

SCHP16 / static Co – 130,0 kN / dynamic C – 84,0 kN

GXSW14.29MS / static Co – 70,0 kN / dynamic C – 50,5 kN

GXSW16.32MS / static Co – 88,0 kN / dynamic C – 63,0 kN

RG14 MT.29 / static Co – 69,8 kN

RG16 MT.32 / static Co – 87,8 kN

Materials

In the manufacture of our products we use the following materials:

1.4057 – high-strength steel, rustproof

1.7225 / 1.7227 – tool steel, alloyed tempered

1.0718 – free-cutting steel, browned

1.4305 – stainless steel

EN AW-7075 T6 / EN AW-6082 T6 – high-strength aircraft aluminium

All parts produced by us have material certificates